Wearable and Battery-Free ‘Sweat Sensor’ to Monitor CF Developed at Dutch University

Researchers at Eindhoven University of Technology (Technische Universiteit Eindhoven-TU/e), in the Netherlands, have developed a device that takes in water at one end and ‘pumps’ it to the other, maintaining the flow without external power. This so-called ‘sweat sensor’ could be a useful tool in assessing certain conditions, including cystic fibrosis.

Researchers at Eindhoven University of Technology (Technische Universiteit Eindhoven-TU/e), in the Netherlands, have developed a device that takes in water at one end and ‘pumps’ it to the other, maintaining the flow without external power. This so-called ‘sweat sensor’ could be a useful tool in assessing certain conditions, including cystic fibrosis.

Observing that plants and trees draw water from the soil by letting it vaporize through pores in their leaves, the TU/e scientists incorporated this principle into a sensor through which perspiration flows at a steady rate, allowing it to be analyzed. Using laser micro-manufacturing, the researchers engineered minuscule structures formed in flexible plastic with an integrated small analytic chip. This device overcomes an important obstacle to the development of flexible sweat sensors that can be placed on the skin — external power source needs.

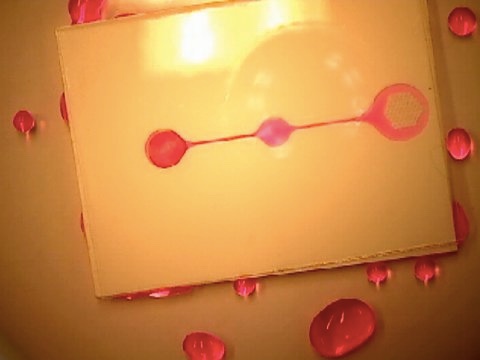

According to a TU/e press release, the left side of the device is for water intake while on the right is a porous structure through which water evaporates, continuously driving the water flow, as seen in the photo above.

The researchers noted that substances in perspiration reveal much about a person’s health, potentially making the device a valuable tool for assessing medical conditions. For instance, saline concentration in sweat can inform about cystic fibrosis, while its acidity level is a determinant factor in certain skin diseases. In order to monitor the development of such conditions over time, fresh perspiration must be constantly conducted through a sweat sensor, preferably one that has no moving or vulnerable parts, and uses no batteries or other power sources — like the TU/e scientists’ device, an innovation that can also be a valuable asset for athletes.

The device was co-developed by Dr. Chuan Nie, PhD, who received his doctorate on Tuesday, April 5, at TU Eindhoven from his mentor and supervising professor, Jaap den Toonder, chair of the Microsystems group at TU/e’s Mechanical Engineering department.

In the TU/e Microfab lab, Dr. Nie and Dr. den Toonder created a device made of flexible plastic foil with an inlet at one end, and a micro-channel connecting it to the other end, which has a porous structure. Using special paper at the inlet, the device soaks up sweat. The moisture is then transported by the capillary action of the channel, and vaporization in the porous structure sustains a constant flow, just as in trees and plants, working like a kind of self-powered water pump.

The research team also integrated a microchip into the device, whose electrodes are inserted onto the channel, enabling them to constantly analyze sweat as it passes through. Dr. Nie built a prototype that measures the acidity level and showed that it worked effectively. Chips that assess other substances in perspiration can also be integrated.

The research was performed in collaboration with Holst Centre in Eindhoven, an independent and open-innovation R&D center set up in 2005 by imec (Flanders, Belgium) and TNO (the Netherlands) with support from the Dutch Ministry of Economic Affairs and the government of Flanders. The Holst Centre develops generic technologies for Wireless Autonomous Sensor Technologies and Flexible Electronics. A key feature of Holst Centre is its partnership model with industry and academia, based around shared roadmaps and programs — the sort of cross-fertilization that enables the Centre to tune its scientific strategy to industrial needs. The Holst Centre is named after Gilles Holst, a Dutch pioneer in Research and Development and the first director of Philips Research. Located on High Tech Campus Eindhoven, Holst Centre benefits from the state-of-the-art onsite facilities.

The research was performed in collaboration with Holst Centre in Eindhoven, an independent and open-innovation R&D center set up in 2005 by imec (Flanders, Belgium) and TNO (the Netherlands) with support from the Dutch Ministry of Economic Affairs and the government of Flanders. The Holst Centre develops generic technologies for Wireless Autonomous Sensor Technologies and Flexible Electronics. A key feature of Holst Centre is its partnership model with industry and academia, based around shared roadmaps and programs — the sort of cross-fertilization that enables the Centre to tune its scientific strategy to industrial needs. The Holst Centre is named after Gilles Holst, a Dutch pioneer in Research and Development and the first director of Philips Research. Located on High Tech Campus Eindhoven, Holst Centre benefits from the state-of-the-art onsite facilities.

Holst and TU/e will continue to develop Drs. Nie and den Toonder’s flexible sweat sensor for the medical analysis of sweat, and as a sports application. Since the device uses plastic foils, the final production costs are expected to be low. One of the next goals will be to set up wireless transmission of the sensor’s data.

TU/e profiles itself as an international engineering science- and technology-specialized research university, training engineers to possess a sound scientific basis and scientific depth, and skills necessary to flourish and contribute to the advancement of technical sciences and research.

The TU/e says it wants to give significant impetus to the knowledge-intensive industries and other social sectors with a high or rapidly evolving technology-intensity, and places emphasis on ‘knowledge valorization,’ or research results able to be translated into innovations and serve as a basis for creating new products, processes, and enterprises. The university encourages students and staff to opt for entrepreneurship.

Sources:

Technische Universiteit Eindhoven (TU/e)

Holst Centre